Gear

Latest about Gear

-

-

Best guitar amp headphones 2026: practice your guitar quietly with my top picks

By Matt McCracken Last updated

-

Best patch cables 2026: put your pedalboard in order

By Ross Holder Last updated

-

Best guitar tuners 2026: clip-on, pedal, and app-based tuning options for all guitarists

By Matt McCracken Last updated

-

Best reverb pedals 2026: embolden your guitar tone with my top-rated reverb pedals

By Connor Godfrey Last updated

-

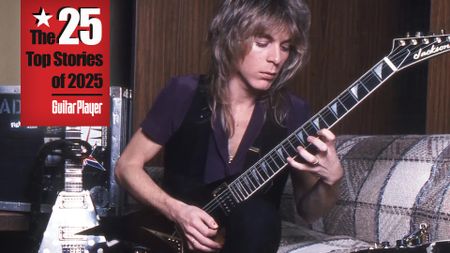

Randy Rhoads’ constant practice drove Ozzy Osbourne crazy. The solution? A tiny pedalboard designed to please them both

By Christopher Scapelliti Published

-

How the Beach Boys' Dumble Overdrive Special ended up in Hawaii, and the celebrity who’s now recording with it

By Phil Weller Published

-

Win tickets to see the Johnny A. Trio at a special Guitar Player Presents event in Oakland, California

By Jimmy Leslie Published

-

Explore Gear

Amps

-

-

How the Beach Boys' Dumble Overdrive Special ended up in Hawaii, and the celebrity who’s now recording with it

By Phil Weller Published

-

Chris Buck and Ariel Posen are fans. Now you can get $600 off Victory Amplification’s V40 Deluxe Duchess head during Cyber Week

By Christopher Scapelliti Published

-

Black Friday guitar deals 2025: these deals are already live – plus all the info you need ahead of the year's biggest guitar sale

By Matt McCracken Last updated

-

Get the sound Adam Jones and James Hetfield made famous for less than $100 during Sweetwater's Black Friday sales event

By Christopher Scapelliti Published

-

A massive $200 discount on a plug-in suite featuring four iconic amplifiers from one of the brands at the forefront of digital amp emulation tech. This Universal Audio offer is one that can't be missed

By Pete Emery Published

-

Who says modelling has to be complicated? Pick up a Line 6 POD Express and see how simple it can be, whilst saving $50 at Guitar Center

By Pete Emery Published

-

A Friedman amp for $99? This none more Black Friday deal is hard to resist

By Rob Laing Published

-

We gave the PRS Archon 50 a five-star review. Get up to $200 off right now during Sweetwater's Black Friday sale

By Christopher Scapelliti Published

-

All three of Positive Grid's 5-star rated Spark amps are on sale for Black Friday – plus $50 off the brand new Bias X software

By Daryl Robertson Published

-

Live Studio

-

-

Best guitar amp headphones 2026: practice your guitar quietly with my top picks

By Matt McCracken Last updated

-

Win tickets to see the Johnny A. Trio at a special Guitar Player Presents event in Oakland, California

By Jimmy Leslie Published

-

We review Solid State Logic’s 2+ MKII digital audio interface and find a feature-packed box guitarists will love

By Christopher Scapelliti Published

-

Positive Grid’s Spark Neo headphones had our reviewer feeling like he was recording in a pro studio

By Christopher Scapelliti Published

-

Orianthi performs at Guitar Player Presents in Oakland, California — Win Tickets

By Jimmy Leslie Published

-

Best acoustic guitar mics 2026: our expert pick of the best mics for recording acoustic guitar

By Simon Fellows Last updated

-

I’ve been recommending this audio interface all year and it just got its first-ever discount for Cyber Monday

By Matt McCracken Published

-

Improve your studio workflow and save $200 on the UA Apollo Twin X DUO Gen 2 during Sweetwater's Cyber Monday sale

By Christopher Scapelliti Published

-

Go wireless for less: Positive Grid Spark Link is just $99 this Black Friday

By Scott Rowley Published

-

Pedals & Pedalboards

-

-

Best patch cables 2026: put your pedalboard in order

By Ross Holder Last updated

-

Best reverb pedals 2026: embolden your guitar tone with my top-rated reverb pedals

By Connor Godfrey Last updated

-

Strymon launches its new Series A line of analog pedals with the Fairfax, a “full tube amp circuit” in a pedal

By Elizabeth Swann Published

-

The Wampler Tumnus is the one pedal that will never leave my 'board, and its golden Klon-style overdrive goodness is now even cheaper for a limited time!

By Rob Laing Last updated

-

I stand by the Boss RE-202 as one of the most convincing tape echo pedals around - and you can still bag a hefty 21% off in this last-minute Cyber Monday saving

By Christopher Scapelliti Last updated

-

Christone "Kingfish" Ingram calls it one of the five pedals he can't do without - and luckily, the MXR FOD Drive is still less than $100 in Sweetwater's Cyber Week sale

By Christopher Scapelliti Last updated

-

It’s the preamp pedal heard on tracks by The Edge, Noel Gallagher and countless others. Now it’s 25% off during Cyber Monday

By Christopher Scapelliti Published

-

This Klon-style overdrive is nearly 50% off for Black Friday. At just $99, it’s the best way to get the sound favored by John Mayer, Jeff Beck and Warren Haynes

By Christopher Scapelliti Last updated

-

Beatles and Brian May guitar tones for $99 – is Sweetwater sure this Tech 21 SansAmp amp pedal deal isn't a misprice?

By Rob Laing Published

-

More about Gear

-

-

Win tickets to see the Johnny A. Trio at a special Guitar Player Presents event in Oakland, California

By Jimmy Leslie Published

-

Strymon launches its new Series A line of analog pedals with the Fairfax, a “full tube amp circuit” in a pedal

By Elizabeth Swann Published

-

Black Friday and Cyber Monday might be over, but these 69 deals for guitarists are still live – act fast before they're gone forever

By Matt McCracken Published

-