News

Latest News

A new Van Halen album features Eddie, Alex and Wolfgang Van Halen playing classic tracks without a vocalist

By Elizabeth Swann published

The album features recordings made by filmmaker Andrew Bennett during his time documenting Van Halen from 2006 to 2007

The “accidental” 1976 smash hit created by a virtuoso rock group and the most recorded guitarist in history

By Joe Matera published

Louie Shelton and the founding members of Toto didn’t think the song had “a chance in hell” of succeeding. A DJ proved them wrong

Olivia Rodrigo on St. Vincent’s signature model and the power of women in rock

By Phil Weller published

The design is aesthetically and ergonomically satisfying. Or as Rodrigo says, “It’s such a f**king cool-looking guitar”

Steve Morse says “a couple of guys in Deep Purple” were glad to see him go

By Phil Weller published

Morse left Deep Purple in 2022 having spent more time in the band than any other guitarist

Ace Frehley said one of his greatest Kiss guitar solos was written by someone else

By Phil Weller published

The track, from the band’s ‘Destroyer’ album, is among the best known in their catalog

Paul McCartney on seeing Jimi Hendrix perform to an empty club — and those rumors about their supergroup with Miles Davis

By Phil Weller published

It could have been the perfect union following the Beatles' break up

Greg Lake on what happened when Robert Fripp asked him to play bass on King Crimson's debut album

By Phil Weller published

It took just one eye-opening rehearsal for Lake to learn the difference between playing guitar and bass

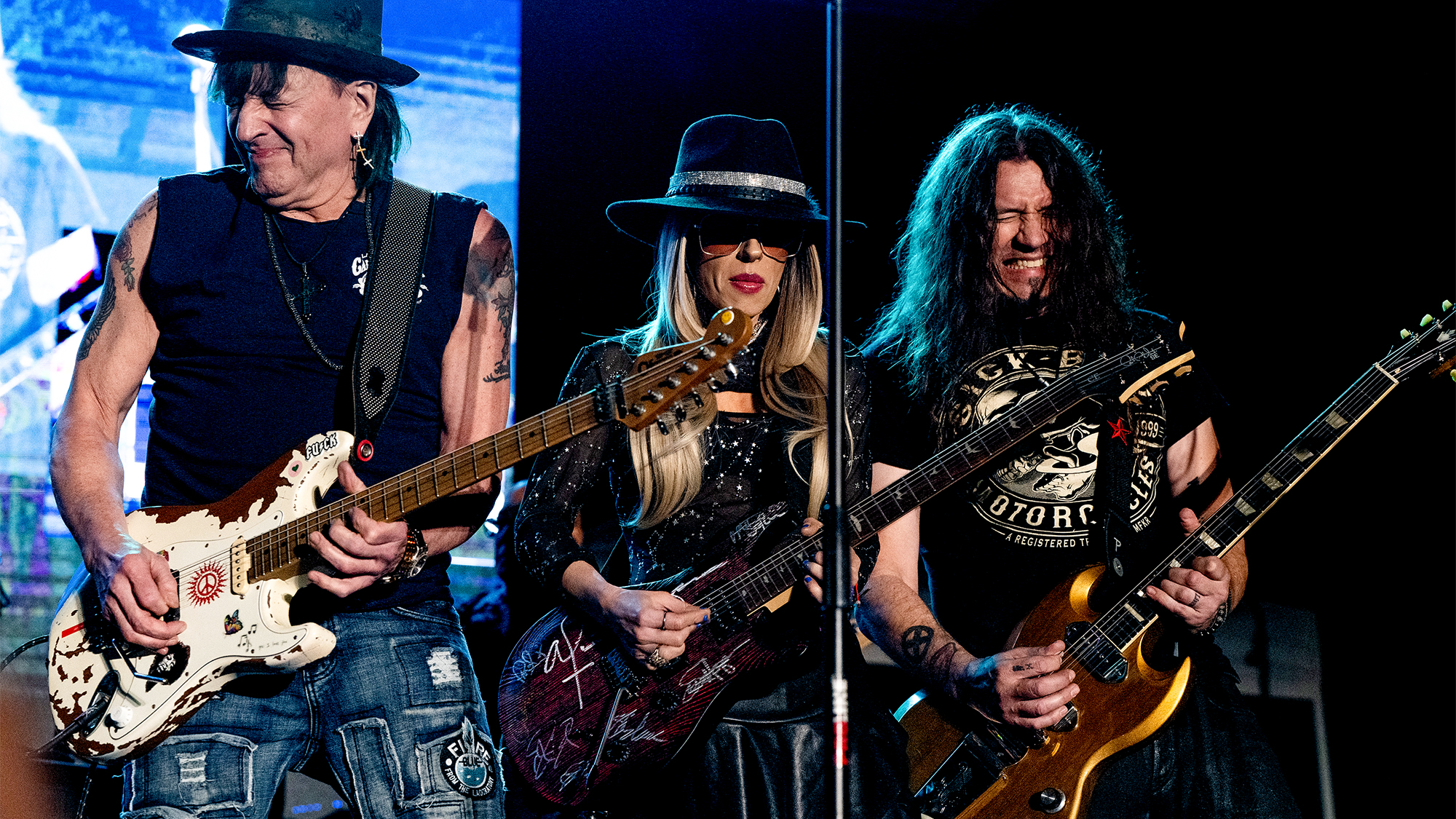

From Cinderella’s Tom Keifer to Keith Urban — how a vintage Fender “Nocaster” made a cross-genre commute

By Phil Weller published

The 1950s guitar was perhaps regretfully sold, with one Tele obsessive the beneficiary of a bad decision

All the latest guitar news, interviews, lessons, reviews, deals and more, direct to your inbox!